Sometimes the biggest breakthroughs come from solving the "unsolvable" problems that everyone else has given up on – this food manufacturer discovered how the right consultant turned a lingering operational challenge into a major competitive advantage.

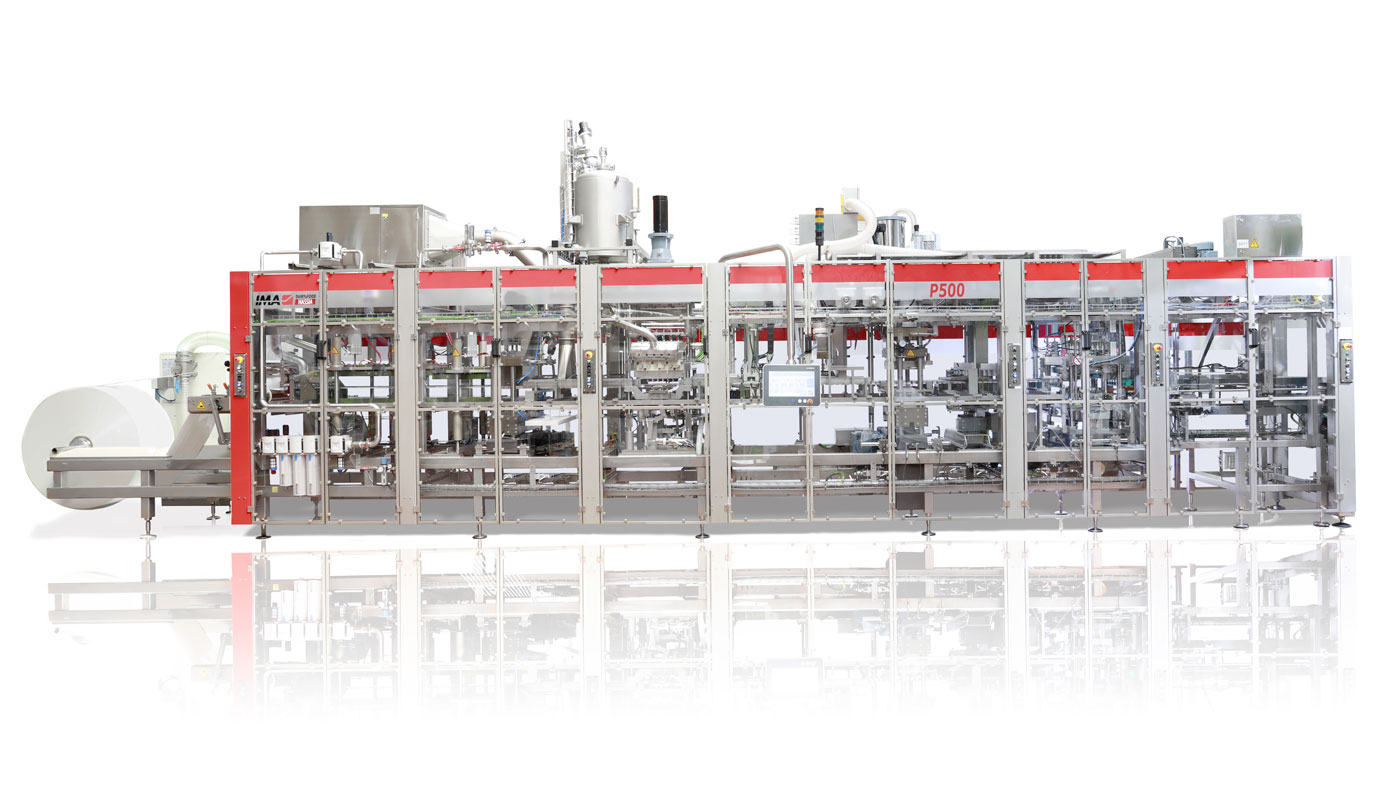

A food manufacturer had successfully launched their new production line – the system worked well and met all operational requirements. However, there was one nagging issue that had been left unresolved: the inability to efficiently switch between certain product SKUs.

The Persistent Problem: The production line couldn't seamlessly transition from layered full-width products to 50/50 flavor combinations (full cup of one flavor on each side). Every changeover required:

Why It Remained Unsolved: While the original installers had proposed solutions, they required expensive modifications to piping systems that had just completed months of rigorous testing. Management wasn't confident enough in these costly proposals to justify restarting the entire validation process and delaying the full production launch for what seemed like an efficiency enhancement.

The problem sat on the back burner – a known inefficiency without a clear path forward.

What management didn't initially realize was the massive financial impact of this "minor" inefficiency. The frequent shutdowns and changeover procedures were quietly draining hundreds of thousands of dollars annually from their bottom line.

The Real Cost:

This wasn't just a technical annoyance – it was a significant profit leak that compounded every single day.

Our client approached this challenge differently. Rather than accepting that expensive physical modifications were the only path forward, they conducted a comprehensive evaluation to uncover alternative solutions.

The Strategic Approach:

The breakthrough came when our client identified that the solution wasn't mechanical – it was programmatic. What others saw as a hardware limitation was actually a software opportunity.

Instead of expensive piping modifications and months of re-testing, our client developed a software-based solution that achieved the desired flexibility without any physical changes.

The Game-Changing Approach:

After rigorous government food safety testing and validation, the solution was approved and ready for implementation.

The solution exceeded all expectations, delivering results that transformed operations and profitability.

Total Investment:

Annual Impact:

Operational Excellence:

This case perfectly illustrates how the right consultant can see opportunities where others see obstacles. While previous evaluators focused on expensive hardware solutions, our client identified an elegant software approach that delivered superior results at a fraction of the cost.

The ROI Story: A $13,000 investment now generates hundreds of thousands in annual savings, year after year – turning a lingering operational challenge into a permanent competitive advantage.

Have operational challenges that seem too expensive or complex to solve? The right consultant doesn't just provide solutions – they uncover hidden opportunities that others miss entirely.

Disclaimer: The images and graphics used on this website may be AI-generated. Case studies and testimonials are based on the owner's personal experiences and may not reflect the actual performance or results of Gramm Solutions LLC or its clients. The information provided is for general informational purposes only and should not be considered as professional advice.