When a manufacturing facility is trapped in a devastating cycle of equipment failures threatening profitability and worker safety, the right strategic equipment optimization approach can eliminate $500K+ in annual losses – this client discovered how a comprehensive system audit, bold standardization proposal, risk-mitigated implementation, and optimized infrastructure design transformed their operations.

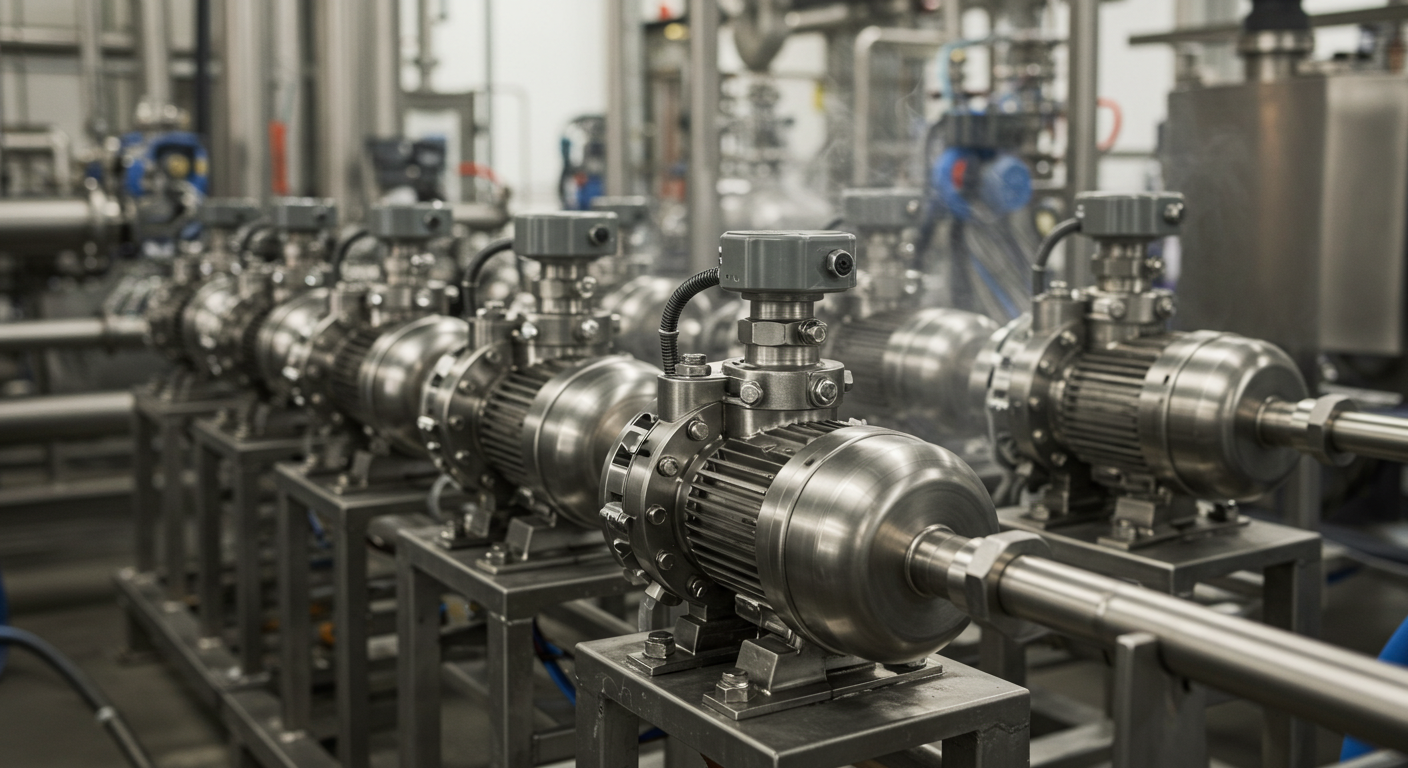

This manufacturing facility was trapped in a devastating cycle of equipment failures that threatened both profitability and worker safety. Eleven different pump models across 24 critical production locations were creating a maintenance nightmare that went far beyond simple repair costs.

The maintenance team was stuck in reactive mode, never able to get ahead of the failure cycle. Production schedules were constantly at risk, and the variety of pump models made inventory management and repair logistics a logistical nightmare.

Rather than continuing the expensive cycle of repairs and replacements, a comprehensive equipment optimization and standardization strategy was implemented.

The counterintuitive solution: replace all 11 pump models with a single, lower-cost alternative that could meet 100% of operational demands while dramatically simplifying maintenance and inventory.

Beyond equipment replacement, piping configurations and system designs were optimized to reduce stress and extend equipment life.

The transformation delivered both immediate relief and long-term competitive advantage:

Operational Excellence:

Strategic Advantages:

This case demonstrates how professional engineering analysis can uncover hidden costs that internal teams often accept as "normal." The client's maintenance team was skilled and dedicated, but lacked the objectivity and specialized expertise to challenge fundamental assumptions about their equipment needs.

Professional optimization delivers value that internal resources cannot:

The $493K annual savings represents just the measurable financial impact – the strategic value of predictable operations, improved safety, and simplified management creates competitive advantages that compound over time.

Is your facility trapped in expensive maintenance cycles that seem "normal" but are actually costing hundreds of thousands annually? Let's discuss how equipment optimization analysis could transform your operations.

Disclaimer: The images and graphics used on this website may be AI-generated. Case studies and testimonials are based on the owner's personal experiences and may not reflect the actual performance or results of Gramm Solutions LLC or its clients. The information provided is for general informational purposes only and should not be considered as professional advice.